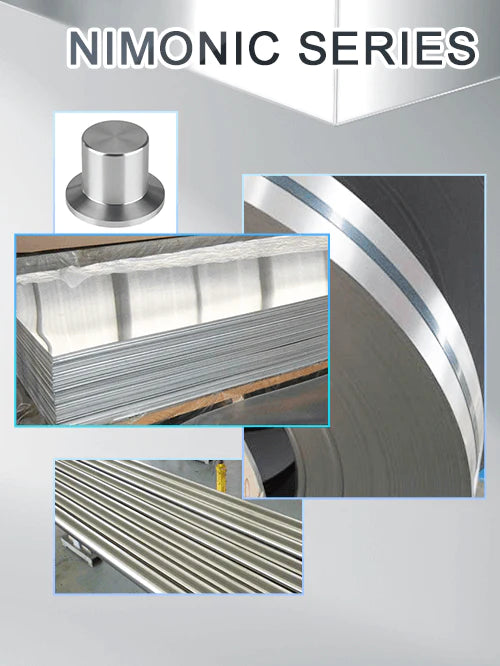

Nimonic 86

Essential details

NIMONIC® alloy 86 has been developed to provide a material with good workability, ductility and weldability, high creep strength and exceptionally good cyclic oxidation resistance at 1050°C.

The alloy is of the solid solution type and it is intended principally for use in high temperature applications such as gas turbine combustion chambers, afterburner parts and heattreatment furnace equipment.

Applications:

- Gas turbine engineering

- Industrial furnaces

- Combustion chambers

Get a free Quote

Call us:

+86-21-67890007

Visit us:

Building #32, No.288 Xinzhuan Road, Songjiang District, Shanghai, China 201612

Email us:

inquiry@ninesteel-cs.cominquiry-carbon@ninesteel-cs.cominquiry-ru@ninesteel-cs.com

Get a free Quote

Tel:+86-21-67890007

Tel:+86-21-67890007

E-mail:inquiry@ninesteel-cs.com

E-mail:inquiry@ninesteel-cs.com

Inquiry Now

Inquiry Now