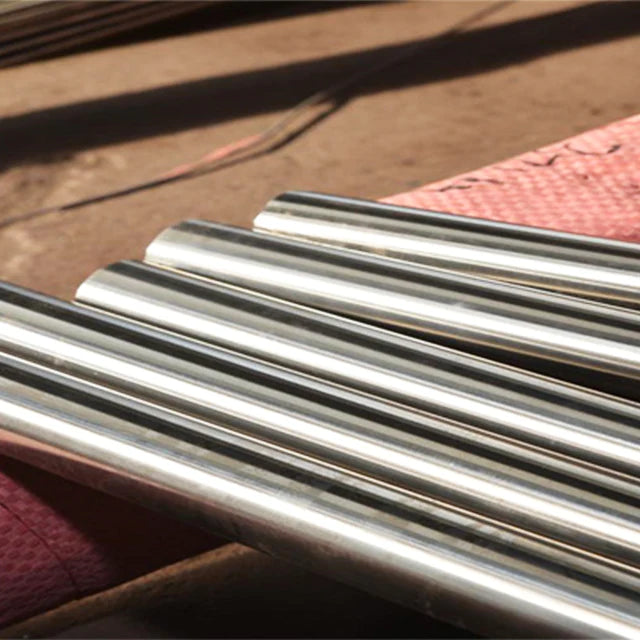

Hastelloy C-4

Hastelloy C-4 offers resistance to mineral acids, organic and inorganic acids, sea water and brine solutions. It has service temperature up to 1900℉ or 1038℃. Outstanding resistance to high temperature corrosion and stress corrosion cracking. Great material for use in chemical processing plants and nuclear fuel processing.

Applications:

- Pollution control stack liners, ducts, dampers, scrubbers, stack-gas reheaters, fans and fan housings

- Flue gas desulfurization systems

- Chemical processing components like heat exchangers, reaction vessels, evaporators, and transfer piping

- Sour gas wells

- Pulp and paper production, waste treatment

- Pharmaceutical and food processing equipment

Get a free Quote

Get a free Quote

Tel:+86-21-67890007

Tel:+86-21-67890007

E-mail:inquiry@ninesteel-cs.com

E-mail:inquiry@ninesteel-cs.com

Inquiry Now

Inquiry Now